Cannabis Oil Recipe that Can Treat Cancer

For a long time, cannabis, also known as marijuana, has been considered just a drug with psychoactive effects. Recently, scientists have discovered that the THC component in the cannabis plant has anti-cancer properties. Although the delta-9 tetrahydrocannabinol (THC) component has been known since the 60s, its anti-cancer properties have been discovered only recently.

Studies have also showed that the cannabinoid molecules in the plant bind perfectly with receptors that are already in the human body, resulting in endocannabinoids that have many positive effects, including the regulation of cell growth. This means that our bodies don’t find this plant harmful, on the contrary.

The most common way to consume cannabis is to smoke it, but the excess chemicals resulting from the fire are an unnecessary damage that can be avoided. Rick Field was one of the pioneers in the field of medical cannabis. He perfected the cannabis oil recipe and released it to the world.

Steps to Prepare Cannabis Oil

You can use one ounce of dried cannabis which will produce 3-4 grams of oil. Be very careful when you boil solvent off because the fumes that are released are extremely flammable. Do not smoke, and avoid stove-tops, sparks and red-hot heating elements. You should set up a fan that will blow the fumes away.

Step 1.

Put some dry cannabis in a plastic bucket and dampen it with solvent. You can use ether, pure naphtha, 99% isopropyl alcohol, butane or even water. You will need two gallons of solvent to extract the THC compound from one pound of cannabis and 500 ml for an ounce.

Step 2.

Use a clean stick to crush the plant. Although the cannabis is damp, you can still crush it because it was completely dry when you started the process. Add solvent to soak the plant completely and stir the mixture for 3-4 minutes. During this process, the THC will dissolve in the solvent.

Step 3.

Pour the resulted solvent-oil mixture into a clean bucket. At this point, you have obtained 80% of THC from the plant. Add again some solvent and stir for another three minutes to get out the remaining THC. Pour the resulted oil into the first bucket that contains the first oil you obtained and threw the twice washed material. Strain the oil through a coffee filter.

Step 4.

Boil the solvent off. For the best result, you can pour some of the mixture into a rice cooker until it’s 3/4 full. Turn to high heat and set up a fan to blow the solvent fumes away. While the solvent evaporates, continue to add mixture until you have added it all. When all the solvent seems to have evaporated, add about ten drops of water for a pound of material to release any solvent residue. The oil should not reach over 140 degrees C (290 degrees F).

Step 5.

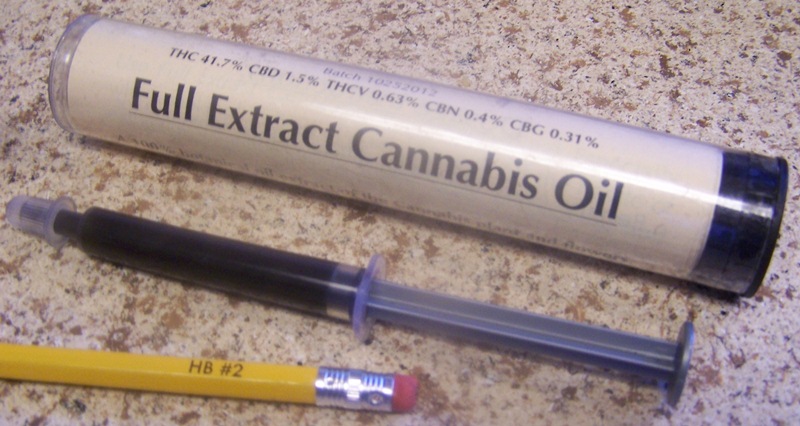

When about one inch of the water-solvent is left, swirl the content until all solvent has boiled off. Pour the resulted oil into a stainless steel recipient and place it into a dehydrator or in a coffee warmer. Leave for a few hours until there is no longer surface activity on the oil. This means that all the volatile terpenes and water has evaporated. Suck the oil into a sterile syringe for safe and easy storage. When it cools, the oil will have the consistency of a thick grease.

The treatment is done slowly, over a period of 90 days (for 60 ml of oil treatment). The resulted oil can be ingested, applied on the skin or used under the form of suppositories.